What can we learn from Lean evolution story? Does it hold the key to successful Lean journey? It does.

I have been in Lean consulting for more than 14 years now, and realize, there is least or no emphasis given to lean evolution journey by many! Most skip this part as it doesn’t talk about tools and techniques. Let us look back and understand what we need to learn from how Lean devised over years.

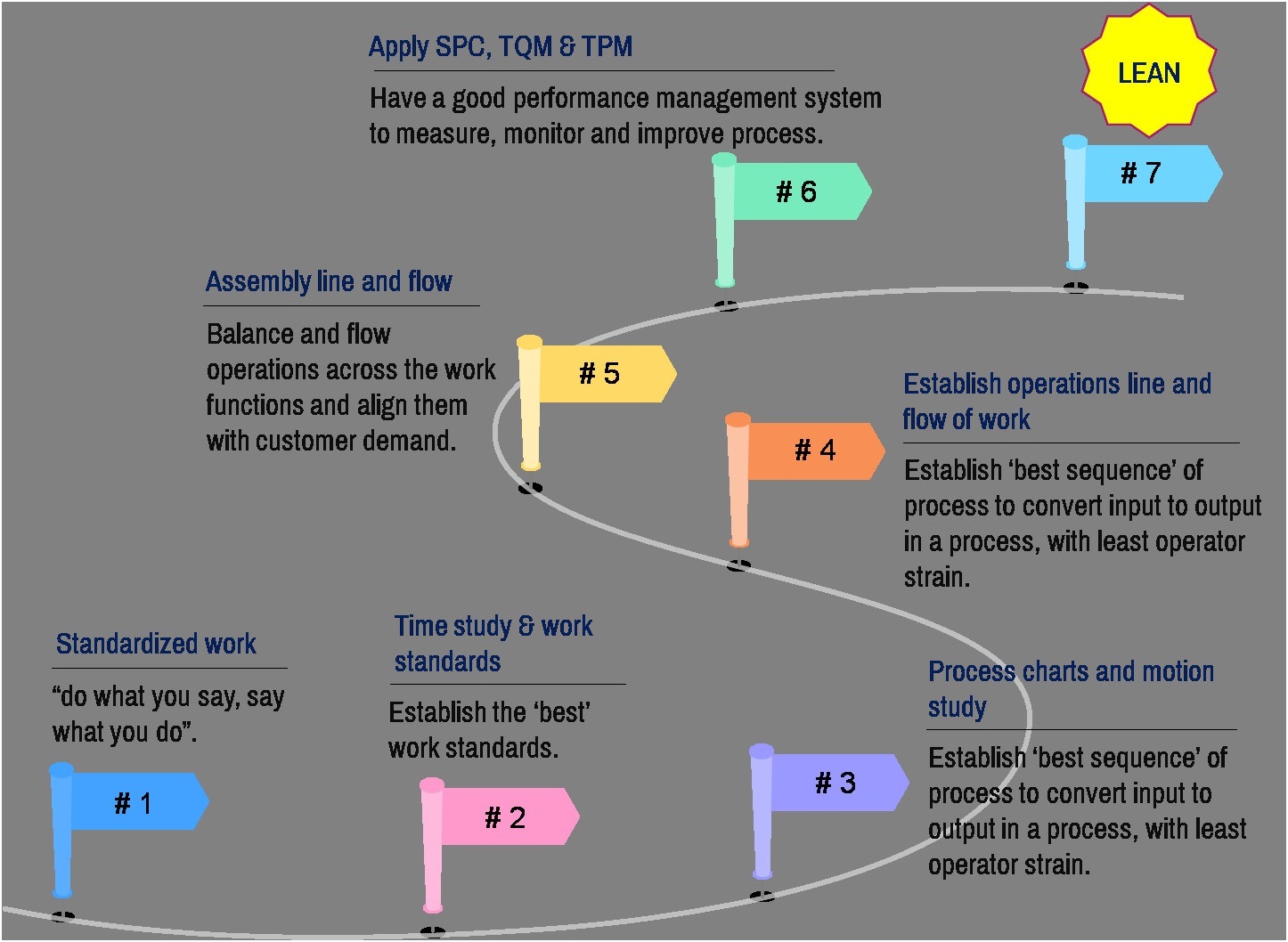

Below is the list of several foundation practices which devised much before Lean did. I have mentioned them around time they devised. What were these practices, what was their purpose? Let us explore. These practices came into existence in the same order as mentioned below.

- Standardized work: “Say (document) what you do, and do what you say (document). This is the purpose of ISO as we know.

- Time study and work standards: The systematic investigation and analysis of the motions and the time needed to perform a specific task to seek more efficient methods of production as well as setting time

- Process charts and motion study: The flow process chart is a graphic and symbolic representation of the processing activities performed on the work piece, while motion study involves various motions (ergonomic) involved.

- Assembly line and flow concept: How to sequence the workload in alignment with customer demand and ensure balance and flow of workload across work roles.

- SPC and TQM: SPC is applied to oversee and control a process. Checking and controlling the process ensures that it performs at its full potential. TQM (Total Quality Management) is a structured approach to improve the quality of products and services through constant refinements.

- TPM (Total Productive Maintenance) : In industry, total productive maintenance (TPM) is a system of preserving and improving the integrity of production and quality systems through the machines, equipment, processes, and employees that add business value to an organization.

- Just in time or World class or Lean manufacturing: “Produce to demand” by the customer, who is the next process. World class manufacturing is synonymous with Lean manufacturing today. It is a collection of concepts, which set standard for production for another organization to follow. Japanese manufacturing is credited with pioneer in concept of world-class manufacturing. Some of the techniques are as follows:

- Make to order

- Streamlined Flow

- Smaller lot sizes

- Collection of parts

- Doing it right first time

- Cellular or group manufacturing

- Total preventive maintenance

- Quick replacement

- Zero Defects

- Just in Time

- Increased consistency

- Higher employee involvement

- Cross Functional Teams

- Multi-Skilled employees

- Visual Signalling

- Statistical process control

It took more than 100 years to reach here! Each discovery laid a foundation for the next one. Each discovery after some time led to a renewed need, and therefore a need for new discovery, one after another.

Today companies aim at # 7, without due considerations given to # 1 to 6. Companies lack the foundation practice which is # 1 to 6.

“Where is the money?” Is a good question to ask, but “Where is the foundation?” Is a better question to ask first? Constant firefighting points out absence of foundation practices.

What happens when we try to jump to step # 7 directly in a ladder? We may fall! So companies skip steps # 1 to 6, jump to 7 directly and experience a fall. It is time, we learn from evolution of Lean philosophy.

PS: You may find this e-book useful too : Lean principles simplified

Visit SKIL to know more about Six Sigma Certification, Lean Six Sigma Black Belt, Lean Certification, Project Management, Lean Six Sigma Green Belt, etc.